01

A National Key SRDI "Little Giant" Enterprise

02

Top R&D Team

03

Strict quality control system

04

Advanced production management systems

A National Key SRDI "Little Giant" Enterprise

Our company has been honored as a National Key SRDI "Little Giant" Enterprise—a designation aligned with Germany’s renowned "Hidden Champions," a term popularized by management scientist Hermann Simon. These "Little Giants" are small and medium-sized enterprises that lead their markets through innovation, technological excellence, and specialized expertise.

As of 2024, out of approximately 512,000 industrial manufacturing firms nationwide, only 14,688 have been awarded the national SRDI "Little Giant", with just 2,000 attained the Key SRDI "Little Giant”. JSI proudly stands as the sole company in China’s top hammer drilling industry to receive this honor.

As of 2024, out of approximately 512,000 industrial manufacturing firms nationwide, only 14,688 have been awarded the national SRDI "Little Giant", with just 2,000 attained the Key SRDI "Little Giant”. JSI proudly stands as the sole company in China’s top hammer drilling industry to receive this honor.

Top R&D Team

With nearly 30 years of specialized experience in drilling tools industry, we have built a database that are suitable for a variety of rock conditions. JSI can design customized drilling tools within 48 hours for various rock conditions.

Using digital twins to assist in design. Simulation accuracy is related to product reliability. The company uses SolidWorks 3D modeling and finite element analysis to build a multi-physics simulation platform that can simulate various scenarios such as stress, temperature, and flow.

Lead by our heat treatment engineers, the process team has developed a control model that links process parameters, microstructure, and mechanical properties. By breaking down complex processes into quantifiable control nodes, the yield rate has remained stable at over 99.8%.

Partner with renowned universities to develop new materials for rock drilling tools. Our joint efforts have led to a number of patents. Applying these new materials to manufacture drilling tools enable us to enhance the performance.

The on-site service team has established a two-way data channel that connects operations to the cloud. This allows for data collection of real-time and related parameters of rock drilling tools. Based on the rich experience of test engineers and the company's data, a failure mode analysis with over 90% accuracy in fault attribution can be delivered, ensuring enhanced operational efficiency and reliability.

Using digital twins to assist in design. Simulation accuracy is related to product reliability. The company uses SolidWorks 3D modeling and finite element analysis to build a multi-physics simulation platform that can simulate various scenarios such as stress, temperature, and flow.

Lead by our heat treatment engineers, the process team has developed a control model that links process parameters, microstructure, and mechanical properties. By breaking down complex processes into quantifiable control nodes, the yield rate has remained stable at over 99.8%.

Partner with renowned universities to develop new materials for rock drilling tools. Our joint efforts have led to a number of patents. Applying these new materials to manufacture drilling tools enable us to enhance the performance.

The on-site service team has established a two-way data channel that connects operations to the cloud. This allows for data collection of real-time and related parameters of rock drilling tools. Based on the rich experience of test engineers and the company's data, a failure mode analysis with over 90% accuracy in fault attribution can be delivered, ensuring enhanced operational efficiency and reliability.

Strict quality control system

JSI achieved ISO 9001 certification for our quality management system in 2006 and has maintained its efficient operation ever since.

We uphold a relentless pursuit of excellence at every stage— from raw material selection to process optimization, service standard settlement, and user experience enhancement.

Since implementing the Total Quality Management (TQM) model, we have developed a comprehensive quality management network encompassing the entire product lifecycle. By expanding quality control beyond traditional inspection to include R&D, intelligent manufacturing, precision marketing, and smart services, we have established a quality assurance system characterized by "full participation, full-process control, and full-factor coverage." This systematic approach not only enables scientific management of quality costs but also propels the company from merely "meeting standards" to "exceeding expectations."

We have established an intelligent monitoring system that tracks key process parameters in real-time. This system provides instant alerts for any deviations, ensuring that each process consistently aligns with the process requirement.

A cluster of international leading inspection equipment such as industrial endoscopes, fully automatic three-coordinate measuring instruments, and ultrasonic flaw detection systems, in combination with MES production execution system, enable the intelligent upgrade of quality control from experience-based judgment to data-driven decision-making.

We uphold a relentless pursuit of excellence at every stage— from raw material selection to process optimization, service standard settlement, and user experience enhancement.

Since implementing the Total Quality Management (TQM) model, we have developed a comprehensive quality management network encompassing the entire product lifecycle. By expanding quality control beyond traditional inspection to include R&D, intelligent manufacturing, precision marketing, and smart services, we have established a quality assurance system characterized by "full participation, full-process control, and full-factor coverage." This systematic approach not only enables scientific management of quality costs but also propels the company from merely "meeting standards" to "exceeding expectations."

We have established an intelligent monitoring system that tracks key process parameters in real-time. This system provides instant alerts for any deviations, ensuring that each process consistently aligns with the process requirement.

A cluster of international leading inspection equipment such as industrial endoscopes, fully automatic three-coordinate measuring instruments, and ultrasonic flaw detection systems, in combination with MES production execution system, enable the intelligent upgrade of quality control from experience-based judgment to data-driven decision-making.

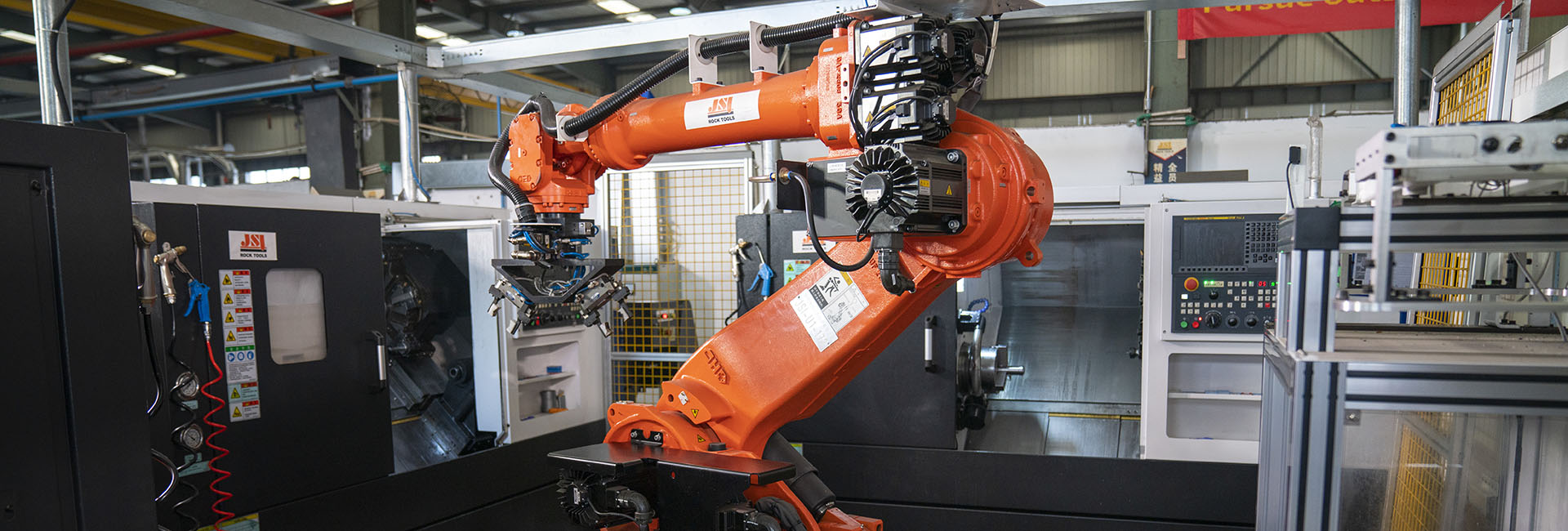

Advanced production management systems

JSI operates two modern production bases located in Guiyang and Chuzhou. In recent years, we have deepened our commitment to digital and intelligent reforms, promoting investments in automation and digitalization. This includes capacity expansion and the implementation of industrial information systems such as centralized control systems. Our equipment transformation—from single machines to integrated and automated units—has allowed us to achieve high-precision control over production processes and maintain exceptional quality stability, significantly enhancing production efficiency.

Phone: +86 851 86780702 / 86780703 / 86788038

Phone: +86 851 86780702 / 86780703 / 86788038 Fax: +86 851 86780950 / 86780960

Fax: +86 851 86780950 / 86780960 Email: marketing@jsirocktools.com

Email: marketing@jsirocktools.com Address: 1002 Dongbai Rd, Wudang District, Guiyang, Guizhou, China

Address: 1002 Dongbai Rd, Wudang District, Guiyang, Guizhou, China SEND

SEND